| Business Type | Manufacturer, Exporter, Supplier |

| Technical Data 01 | |

| Technical Data 02 | |

| Technical Data 03 | |

| Click to view more | |

Product Details

Patented Rotary Filter with simple and safe handling, suitable for almost all applications.

Constant pressure and process consistency

The SFneos Filtration Systems work continuously, process and pressure constant. They can be used for almost all applications and are characterized by their compact design and simple and safe handling. Several screens can be changed at the same time during a screen change process. Screen changes do not have any influence on the product quality.

Specially designed for PVC processing and recycling applications

The Rotary Technology has been used successfully in PVC processing and PVC recycling applications for more than 30 years. The SFpvc Filtration Systems have been specially designed for thermally unstable and chemically aggressive processes such as those occurring in PVC recycling. The rheologically optimised filtration systems with their dead-zone free melt channel design and short flow path allow gentle processing.

The advantages of the SFneos Filtration System

- Constant-By always keeping the size of the free active screen area constant, the pressure can be kept constant during the whole production process (max. pressure variations of ±1,5bar). Also, melt temperature and viscosity are permanently free from variations. Thus, the end product quality is always constant.

- Quality-Melt purity and quality downstream of the filtration system are permanently achieved. Rheologically optimized melt flow channels.

- Streamlined-Due to the optimal rheological flow channel design, the dwell time of all the melt in the filtration system is very short (< 1 minute). No danger of material burning in dead spots.

- Straightforward-The operator is informed in time about upcoming screen changes by the control system. Changing screens is a simple and quick procedure and does not have any influence on the process and product quality.

- Compact size-The compact design of the SFneos makes even in a very confined space a simple and cost-efficient integration possible. Thanks to the compact design and the high quality insulation, the energy consumption is extremely low.

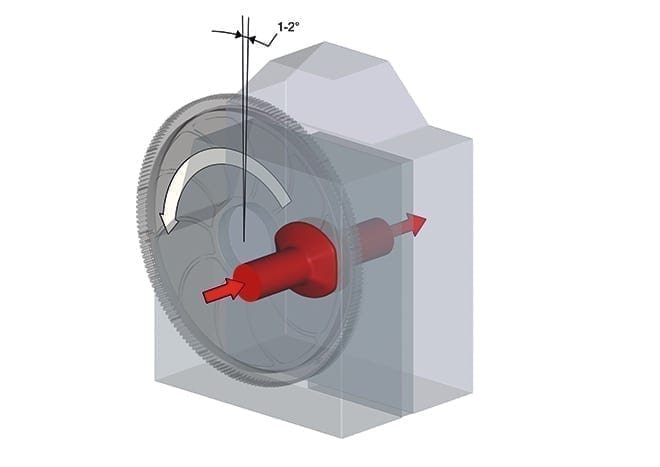

Mode of operation

When a pressure increase upstream of the filter due to contamination is registered, the filter disk is indexed by means of a pneumatic drive. This guarantees that the free screen area is always kept constant and that the pressure variation in front of the filter is < 1.5 bar.

Design

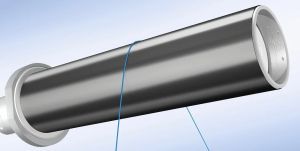

The filter disk – on which the screen cavities are located in a ring pattern – rotates between the two filter blocks. To change the screens, the safety cover has to be opened. The production process is not disturbed by the screen change procedure. Thanks to the modular design of this filtration system, it is possible to replace the few wearing parts (such as heater elements and bearing bushings) during operation. Continuous production over many years is thus made possible.

Graph

Looking for "SFneos Series Filter Screen Changer" ?

Explore More Products