The Online Viscometer was developed with the goal of achieving measurements which are comparable with laboratory results and to provide a system which provides these accurate values permanently and without influencing the process.

Reliable viscosity measurement

The Online Viscometer was developed with the goal of achieving measurements which are comparable with laboratory results and to provide a system which provides these accurate values permanently and without influencing the process.

The viscometer is fitted between two flange connections. The melt channel can be designed according to the customer´s specifications between D = 20 mm (0.8 inches) and D = 110 mm (4.3 inches). The unit includes the pump drive, the pump, pressure transducers, temperature sensors and the control and evaluation electronics. Electric or liquid/vapor heating is available (optional). The setting of process parameters, the evaluation and the display is realized via a user-friendly touch screen panel or alternatively can be integrated into an existing control system.

An easily exchangeable capillary permits the adaptation of the measuring device to different viscosities ranging from 1 mPas (0.01 poise) up to 20.000 Pas (200,000 poise). A subsequent change of the measuring range is also possible.

Due to the special melt channel design and precise fabrication, dead spots or edges in which shear and temperature sensitive polymers could possibly stagnate can be avoided. The very short dwell time also prevents accumulations of degraded material. A further innovative feature is the possibility of completely cleaning all parts in contact with the melt without interrupting or disturbing the production process.

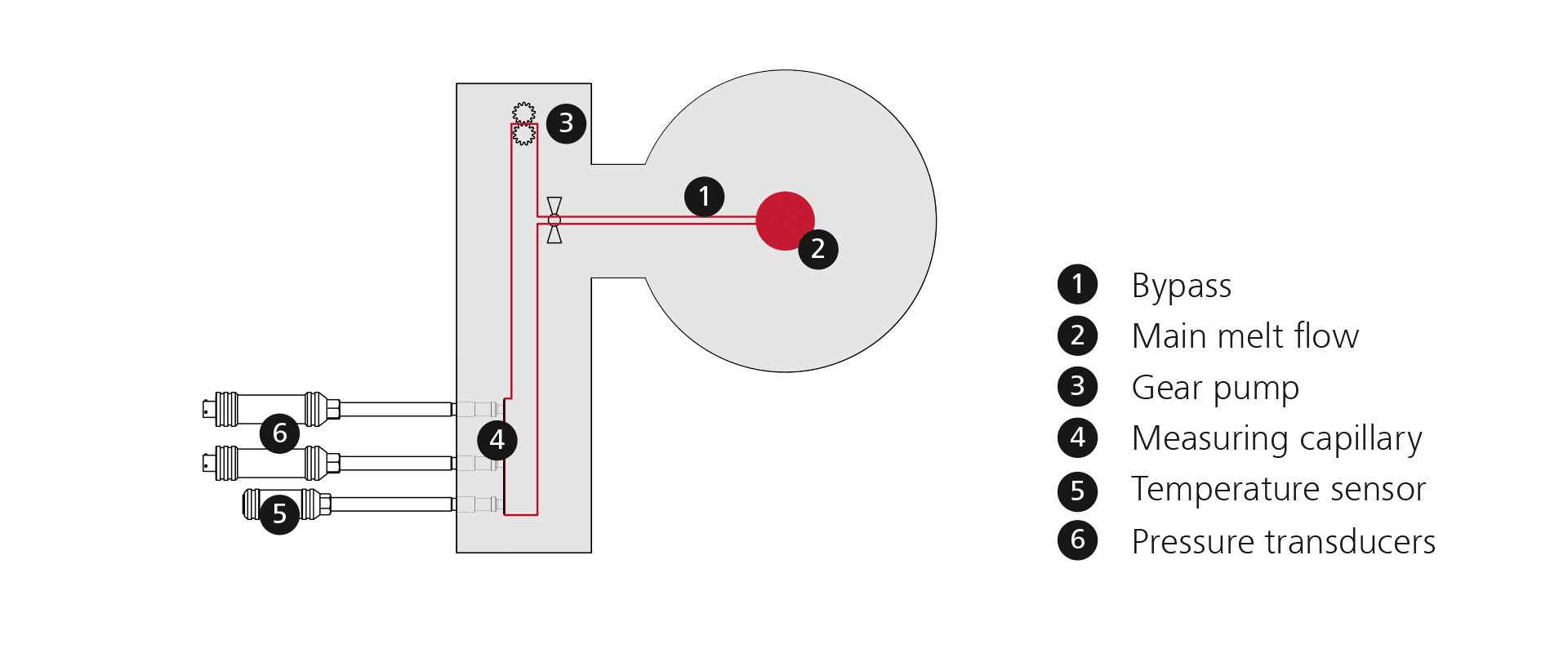

Configuration

By means of a high precision metering gear pump, a small part of the polymer melt (max. 3 kg / h or 7 lbs / h) is separated from the main melt channel. This is pumped through a precisely manufactured slot capillary. The inlet and outlet pressures or the elastic properties which disturb the measurement are filtered out by means of length – optimized inlet and outlet zones in the capillaries for levelling out the laminar flow.

Advantages of the Online Viscometer VIS

- No measurable temperature increase in the rheometer thanks to ample flow channels.

- Short dwell time, no dead spots, no remnants or material left in the melt channels.

- Through measurement in the rectangular capillary cross section – no elastic properties are recorded.

- Very compact design, flexible adaptation to the existing melt pipe or extrusion line.

- Fast adaptation and change of the measuring range through an exchangeable capillary plate.

- Polymer bypass, therefore no melt losses.

- High-precision measurement of the melt temperature directly during the viscosity measurement.

- High measurement accuracy through use of special high-precision pressure transducers.

- Complete cleaning of all surfaces and channels in contact with the melt without interruption or shutting down of the production process.

Graph

Looking for "Online Viscometer Extrusion System" ?

Explore More Products