Filter Screen Changers

Leading Manufacturers, Exporters, Wholesaler of CSFprimus Series Filter Screen Changer, KSF Series Filter Screen Changer, RSFgenius Series Filter Screen Changer, SFneos Series Filter Screen Changer and SFXmagnus Series Filter Screen Changer from Navi Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

| Technical Data 01 | |

| Technical Data 02 | |

| Thickness | 0-50cm, 100-150cm, 150-200cm |

| Certification | CE Certified, ISO 9001:2008 |

| Condition | New |

| Warranty | 2yrs |

| Flow Range | 0-200cfm, 200-400cfm, 400-600cfm, 600-800cfm |

| Country of Origin | India |

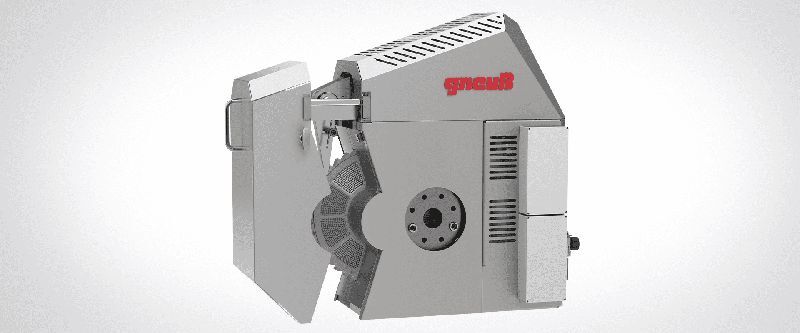

Patented Rotary Filtration System with large active screen area and two working positions.

Continuous and fully-automatic

Patented rotary filtration system with large active screen area and two working positions. The filter disc is divided into two zones, which can be alternately moved into the melt channel. On request (e.g. for batch or roll changes) the positions and thus all screens in the melt channel are automatically changed. The melt flow is not interrupted, so that downstream components do not have to be restarted afterwards. Filter elements can be replaced at any time between two changes.

The advantages of CSFprimus screen changers

- Compact-The small and compact design of the Rotary Filtration Systems makes simple and cost-efficient integration possible even in a very confined space.

- Sturdy-The metallic sealing system is highly wear-resistant. It guarantees leak-free operation even with low viscosity melts up to 500 bar.

- Streamlined-The rheology of the melt channel and the inner parts of the screen changer can be individually adjusted to the specific requirements.

- Uncomplicated-A screen change can be carried out automatically at any time without interrupting the melt flow. In case of a change, all screens in the melt flow are completely exchanged. Such a change should preferably take place during roll/batch changes. If more frequent changes are required during the production batch, a pressure-constant system (SFneos, SFXmagnus or RSFgenius) should be used.

The filter disc is divided into two filter segments which can be alternately introduced into the melt channel. The change is done fully automatically. The system is driven hydraulically or pneumatically.

The segment, which is not located in the melt channel, is completely accessible, so that the operating personnel can replace the filter elements at any time between changes. On request, a version with removable breaker plates is also available, so that even demanding colour changes can be carried out in the shortest possible time.

During the change itself, the melt flow is not interrupted, so that downstream components generally do not have to be restarted after the change.

| Business Type | Manufacturer, Exporter, Supplier |

| Technical Data 01 | |

| Technical Data 02 | |

| Technical Data 03 | |

| Technical Data 04 | |

| Technical Data 05 | |

| Technical Data 06 | |

| Thickness | 0-50cm, 100-150cm, 150-200cm |

| Certification | CE Certified, ISO 9001:2008 |

| Condition | New |

| Warranty | 2yrs |

| Flow Range | 0-200cfm, 200-400cfm, 400-600cfm, 600-800cfm |

| Country of Origin | India |

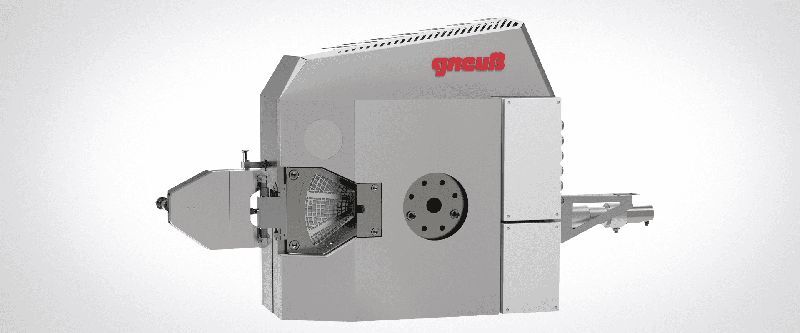

Compact screen changers for applications with frequent material and/or colour changes.

Compact and continuous

The Rotary Filters KF and KSF are simpler continuous screen changers based on the proven concept of the Rotary Filtration Technology. These filter systems are especially suitable for high pressure applications and frequent material changes.

The advantages of KSF screen changers

- Compact-The small and compact design of the Rotary Filtration Systems makes simple and cost-efficient integration possible even in a very confined space.

- Sturdy-The metallic sealing system is highly wear-resistant. It guarantees leak-free operation even with low viscosity melts up to 500 bar.

- Streamlined-The rheology of the melt channel and the inner parts of the screen changer can be individually adjusted to the specific requirements. These screen changers are also perfectly suitable for thermally sensitive polymers such as PVC.

- Straightforward-A screen change can be initiated automatically without the need to stop production.

KSFx2 screen changer with double active area

The KSFx2 Filtration System is characterized by rheologically optimized melt flow channels absolutely free from dead spots. The channels are matched individually to the respective filtration task. When the pressure upstream of the filter increases due to contamination of the screen and the selected pressure value is reached, a screen change is carried out automatically.

During screen changes, polymer flows briefly over 3 screen cavities, thereby avoiding pressure spikes and consequently avoiding process disturbances. It is possible to remove the breaker plates during screen changes and replace them with clean plates. This is especially important for thermally sensitive materials, to make sure that always a 100 % clean cavity and breaker plate enter into the melt flow.

| Business Type | Manufacturer, Exporter, Supplier |

| Technical Data 01 | |

| Technical Data 02 | |

| Thickness | 0-50cm, 100-150cm |

| Certification | CE Certified, ISO 9001:2008 |

| Condition | New |

| Warranty | 2yrs |

| Country of Origin | India |

| Flow Range | 0-200cfm, 200-400cfm |

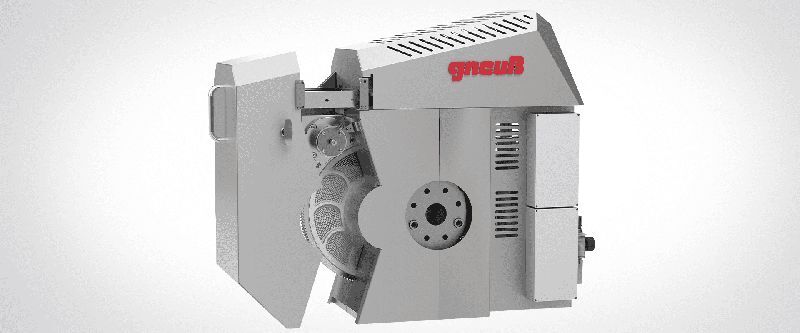

With regard to achievable product quality, economic efficiency and in terms of operator and maintenance friendliness, the RSFgenius offers unrivalled possibilities

Fully-automatic, pressure-constant, permanent process consistency-

With regard to achievable product quality, economic efficiency and in terms of operator and maintenance friendliness, the RSFgenius offers unrivalled possibilities. This fully-automatic and pressure-constant filtration system can be used in virtually any application, for automation of the production process and for the manufacture of a high quality final product. The RSFgenius is particularly well suited for ultra-fine filtration, the filtration of thermally-sensitive melts and the filtration of materials with a high contamination level.

The advantages of the RSFgenius Filtration System-

- Fully-automatic-The filtration system operates fully-automatically and ensures a 100% availability of the line. Depending on the contamination level, a screen change (which takes approx. 20-30 minutes) is carried out approx. every 1-16 weeks and has no influence on the production process and product quality.

- Constant-By always keeping the size of the active screen area constant, pressure, temperature, viscosity and throughput of the melt remain constant, which guarantees the highest end product quality.

- Quality-Optimal flow channel design and encapsulation guarantee lasting purity and quality of the melt after the screen changer. The short dwell time of the melt in the filtration system (< 1 minute) permits quick material or color changes. Filtration finenesses down to 1 micron are possible.

- Simple-Screen changes do not expose personnel and environment to any danger. With the fully encapsulated design of the RSFgenius, influences from the environment (e.g. moisture, oxygen) during the filtration process are excluded. Due to the very effective screen cleaning with high pressure impulses, screens are automatically re-used 100-400 times (depending on the filtration fineness).

- Compact-The small and compact design of the RSFgenius makes a simple and cost-efficient integration possible even in a very confined space. Thanks to the compact design and the high quality insulation, the energy consumption is extremely low.

Mode of operation

A high pressure segmental backflushing system purges the screen packs clean, shortly before their re-entry into the melt channel. A small, measured „shot“ of filtered polymer is taken from the „clean“ (filtered) side of the screen changer and injected with an adjustable pressure of approx. 30 – 80 bar backwards across the screen pack. The backflush is then ejected through the screen changer inlet block to the outside. Only a small segment (approx. 1 %) of the screen area is cleaned at one time. A defined quantity of material delivers a high energy cleaning impulse.

Design

The filter disk – on which the screen cavities are located in a ring pattern – is completely encapsulated by the two filter blocks. Screens can be inserted into the cavities by opening a small hatch door giving access to the cavities. The production process is not disturbed by the screen change procedure. Thanks to the modular design of this filtration system, it is possible to replace the few wearing parts (such as heater elements and bearing bushings) during operation. Continuous production over many years is thus made possible.

Versions

Model versions with special performance features are available to suit the respective application:

- Very high filter surface exchange rate for highly contaminated materials

- Continuous back-flushing for extremely sensitive processes and polymers and/or extremely contaminated materials

| Business Type | Manufacturer, Exporter, Supplier |

| Technical Data 01 | |

| Technical Data 02 | |

| Technical Data 03 | |

| Technical Data 04 | |

| Thickness | 0-50cm, 100-150cm, 150-200cm |

| Certification | CE Certified, ISO 9001:2008 |

| Flow Range | 0-200cfm, 200-400cfm, 400-600cfm |

| Country of Origin | India |

Patented Rotary Filter with simple and safe handling, suitable for almost all applications.

Constant pressure and process consistency

The SFneos Filtration Systems work continuously, process and pressure constant. They can be used for almost all applications and are characterized by their compact design and simple and safe handling. Several screens can be changed at the same time during a screen change process. Screen changes do not have any influence on the product quality.

Specially designed for PVC processing and recycling applications

The Rotary Technology has been used successfully in PVC processing and PVC recycling applications for more than 30 years. The SFpvc Filtration Systems have been specially designed for thermally unstable and chemically aggressive processes such as those occurring in PVC recycling. The rheologically optimised filtration systems with their dead-zone free melt channel design and short flow path allow gentle processing.

The advantages of the SFneos Filtration System

- Constant-By always keeping the size of the free active screen area constant, the pressure can be kept constant during the whole production process (max. pressure variations of ±1,5bar). Also, melt temperature and viscosity are permanently free from variations. Thus, the end product quality is always constant.

- Quality-Melt purity and quality downstream of the filtration system are permanently achieved. Rheologically optimized melt flow channels.

- Streamlined-Due to the optimal rheological flow channel design, the dwell time of all the melt in the filtration system is very short (< 1 minute). No danger of material burning in dead spots.

- Straightforward-The operator is informed in time about upcoming screen changes by the control system. Changing screens is a simple and quick procedure and does not have any influence on the process and product quality.

- Compact size-The compact design of the SFneos makes even in a very confined space a simple and cost-efficient integration possible. Thanks to the compact design and the high quality insulation, the energy consumption is extremely low.

Mode of operation

When a pressure increase upstream of the filter due to contamination is registered, the filter disk is indexed by means of a pneumatic drive. This guarantees that the free screen area is always kept constant and that the pressure variation in front of the filter is < 1.5 bar.

Design

The filter disk – on which the screen cavities are located in a ring pattern – rotates between the two filter blocks. To change the screens, the safety cover has to be opened. The production process is not disturbed by the screen change procedure. Thanks to the modular design of this filtration system, it is possible to replace the few wearing parts (such as heater elements and bearing bushings) during operation. Continuous production over many years is thus made possible.

| Business Type | Manufacturer, Exporter, Supplier |

| Technical Data 01 | |

| Technical Data 02 | |

| Thickness | 0-50cm, 100-150cm |

| Certification | CE Certified, ISO 9001:2008 |

| Warranty | 2yrs |

| Flow Range | 0-200cfm, 200-400cfm |

| Country of Origin | India |

The SFXmagnus series operates automatically as well as process and pressure constant. It is suitable for almost every application.

Constant pressure and process consistency-

The SFXmagnus series operates automatically as well as process and pressure constant. It is suitable for almost every application. This series is characterized by an extra large active screen surface area, its compact design, as well as extremely easy operation. Screen changes do not have any influence on the product quality.

The advantages of the SFXmagnus Filtration System

- Economic-The extra large active screen surface area in relation to the screen changer size allows a unique economic efficiency of the SFXmagnus. The return on investment is realized within a very short period of time.

- Constant-By assuring a consistent active screen area, the pressure can be kept nearly constant during the whole production process. Melt temperature, viscosity and throughput are also free of variations at any time. Constant quality of the final product is guaranteed even during screen changes.

- Quality-Thanks to the optimized melt channel flow path and completely airtight encapsulated design, the requirements with regard to the purity and quality of the melt can be achieved and permamently maintained.

- Streamlined-The optimized rheological design of the melt channel flowpath ensures a minimized residence time (< 1 minute) thus ensuring for example fast material or color changes.

- Straightforward-The control system informs the operator in advance of an upcoming screen change. The screens can be changed quickly and easily and without any influence on the process or pressure consistency.

- Compact-The remarkably compact size of the SFXmagnus allows an easy and inexpensive integration even within limited space. Thanks to the compact design and the high quality insulation, the energy consumption is extremely low.

Mode of operation

When a pressure increase upstream of the filter is registered, the filter disk is indexed automatically by means of a pneumatic or hydraulic drive. The active screen area is always kept constant and the pressure upstream of the filter increases only slightly during the whole production process. After the cavities have passed through the melt flow, the screens can be removed without disturbing the production process.

Design

The filter disk – on which the screen cavities are located in a ring pattern – is completely encapsulated by the two filter blocks. Screens can be inserted into the cavities by opening a small hatch door giving access to the cavities. The production process is not disturbed by the screen change procedure. Thanks to the modular design of this filtration system, it is possible to replace the few wearing parts (such as heater elements and bearing bushings) during operation. Continuous production over many years is thus made possible.